How DAT Works

How DAT Works

The only company in the world to offer

a lifetime guarantee against wear.

Side Locks

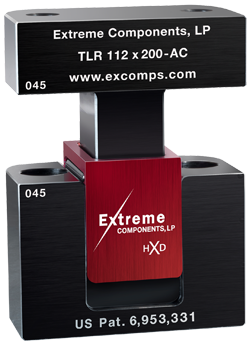

Extreme Components is the creator of the “Zero Friction” needle bearing locks. These locks guarantee exact alignment on every cycle and no wear up to 5 million cycles, giving you the last mold your locks will ever need. Extreme Components offers Nylon Cage Locks and Aluminum Cage Locks for Top Locks, Side Locks and X-Series Locks.

Top Locks

Needle Bearing Top Locks are a relatively new innovation that outperform all previous styles and designs of the various alignment devices. They are the only product of their kind that corrects the problem of misalignment regardless of leader pin wear, worn tie bars or improper mold setting. They eliminate wear within the lock to ensure exact alignment.

X-Series Locks

The new “X-Series” design from Extreme Components adds a new level of precision and flexibility. These locks are built specifically for three plate molds and come in standard sizes that will retrofit perfectly to existing standard sizes that are on the market today. These are available in both plastic and aluminum cage styles, as well as in custom sizes.

EC Nano Locks

The new “X-Series” design from Extreme Components adds a new level of precision and flexibility. These locks are built specifically for three plate molds and come in standard sizes that will retrofit perfectly to existing standard sizes that are on the market today. These are available in both plastic and aluminum cage styles, as well as in custom sizes.

Zero Friction Technology

Needle Bearing Locks are designed to withstand the most demanding requirements in mold alignment, providing precise registration between the two halves of the tool. By utilizing technology that has been used for centuries, we were able to create locks that guarantee perfect alignment, every cycle, as well as eliminate wear caused by friction. Eliminating wear within the locks and providing perfect alignment allows you to maximize the utilization of your tools and materials which ultimately leads to lowered production costs and increased margins.

Needle Bearing Alignment

Needle Bearing Locks are a relatively new innovation that outperform all previous styles and designs of the various alignment devices. It is the only product of its kind that corrects the problem of misalignment regardless of leader pin wear, worn tie bars or improper mold setting. Needle bearings eliminate wear within the lock to guarantee that exact alignment is achieved every cycle over the lifetime of the lock.

Needle Bearing Locks offer precise registration between the two halves of the tool and feature a patented “live cage”, which allows for proper bearing performance, versus pocket-trapped rollers. The new animation illustrates these features and also shows unmatched “lifting power” to overcome misalignment due to platen sag.